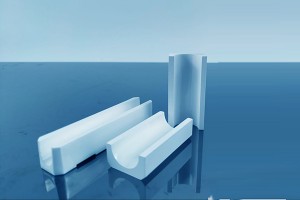

CERAMIC REFLECTOR

The ceramic reflector (ceramic cavity) is made from 99% Al2O3, and the body is fired at suitable temperature to retain appropriate porosity and high strength. The surface of the reflector is fully coated with high-reflectivity ceramic glaze. Compared with the gold-plated reflector, ceramic reflector has main advantages of extremely long service life and high diffuse reflectivity.

WISOPTIC Specifications – Ceramic Reflector

| Material | Al2O3 (99%)+ Ceramic glaze | |

| Color | White | |

| Density | 3.1 g/cm3 | |

| Porosity | 22% | |

| Bending strength | 170 MPa | |

| Coefficient of thermal expansion | 200~500 ℃ | 200~1000 ℃ |

| 7.9×10-6/K | 9.0×10-6/K | |

| Diffuse reflectivity | 600~1000 nm | 400~1200 |

| 98% | 96% | |

Production capabilities:

- Components up to 250mm long and 80mm wide/diameter manufactured as standard

- Partly or totally glazed

- One-piece or split-cavity designs

- Prototype, batch and volume production