3 Functional laser damage evaluation and laser pretreatment technology

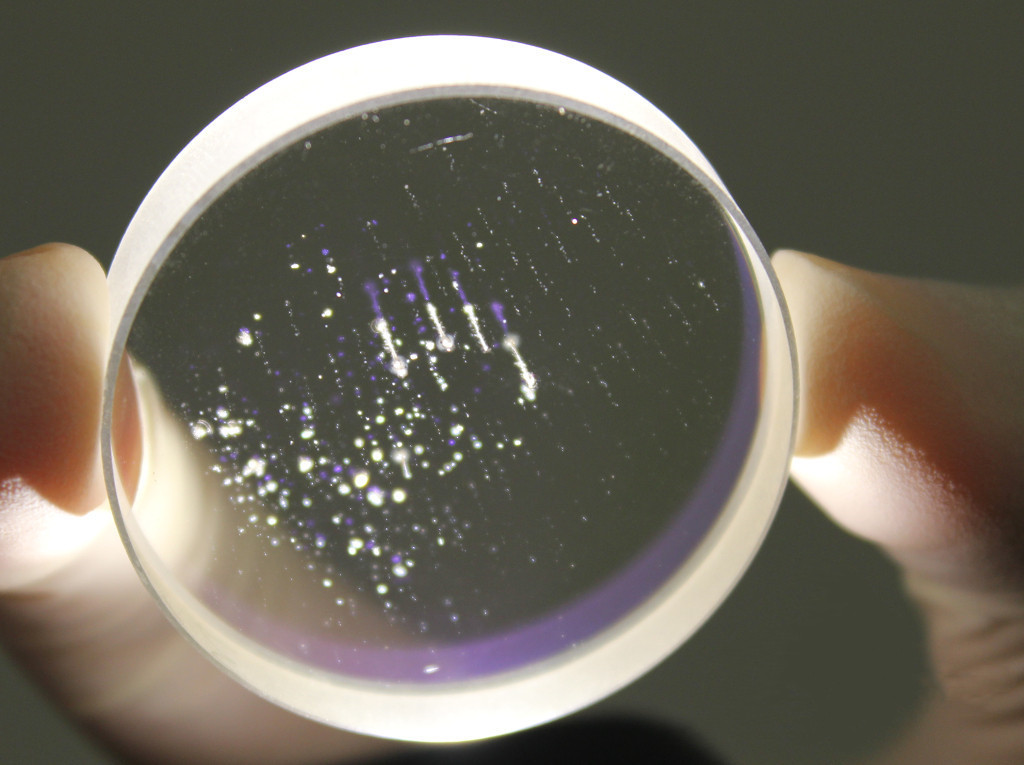

Whether it is microscopic defects or nanoscopic laser damage precursors, the distribution and amount in optical materials or components are closely related to the manufacturing process. Low-defect processing and manufacturing technologies have played an important role in promoting the manufacture of high-power laser materials and components. However, as the largest laser project, the ICF laser driver has the largest number and size of optical components so far. In large-scale projects, it is necessary to avoid laser damage induced by defects and precursors, and to increase the output flux of large-scale lasers. It is unrealistic to expect mass production of “zero-defect” optical materials and components, so it is necessary to balance the contradiction between production capacity and defect control. Based on the fact that the damage induced by defects or precursors is generally a local pit-like structure whose size may be controlled, LLNL in the United States proposed a functional damage threshold evaluation system that tolerates the existence of certain damage points. The size of the damage point is controlled to be the smallest and most stable, and a series of post-processing methods are proposed, among which the laser pre-processing technology has the most engineering application value.

3.1 Functional laser damage threshold evaluation method for large aperture optical components

The so-called functional laser damage is mainly manifested in two aspects: first, the local damage caused by laser irradiation should be small enough to not significantly change the optical properties of the component, such as reflectivity, transmittance, etc., and not significantly change the characteristics of the transmitted beam, so as not to affect the overall function of the components in the system; secondly, this local damage should be stable, and the size growth phenomenon will not occur in multiple irradiation under the design flux conditions of the laser system. Obviously, functional damage should be based on the laser system and component functions, and the damage points should be defined in terms of scale, density, and stability. At present, the US NIF project’s criteria for judging functional laser damage to large-aperture optical components are:

• The transverse dimension of the damage point does not exceed 280 μm;

• The shading area caused by all damage points does not exceed 0.01% of the light-transmitting area of the component;

• Damage spot size does not grow under the subsequent irradiation of laser pulses;

• The proportion of plasma ablation after laser pretreatment of dielectric thin film components shall not exceed 3%.

Post time: Mar-01-2023