OEM/ODM Factory Yag Rods - Nd:YAG Crystal – WISOPTIC

OEM/ODM Factory Yag Rods - Nd:YAG Crystal – WISOPTIC Detail:

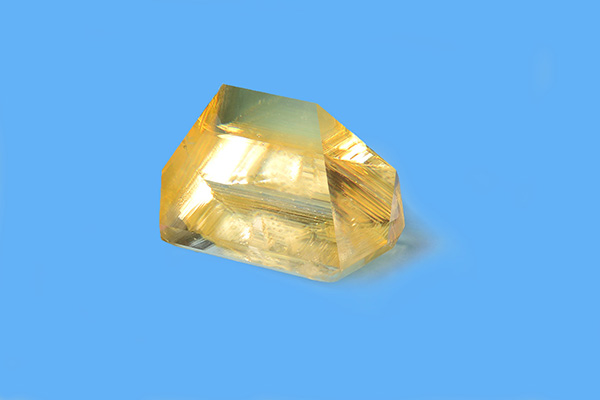

Nd:YAG (Neodimium Doped Yttrium Aluminum Garnet) has been and continue to be the most widely used laser crystal for solid-state lasers. Good fluorescence lifetime (twice more than that of Nd:YVO4) and thermal conductivity, as well as robust nature, make Nd:YAG crystal very suitable for high-power continuous wave, high-energy Q-switched and single mode operations.

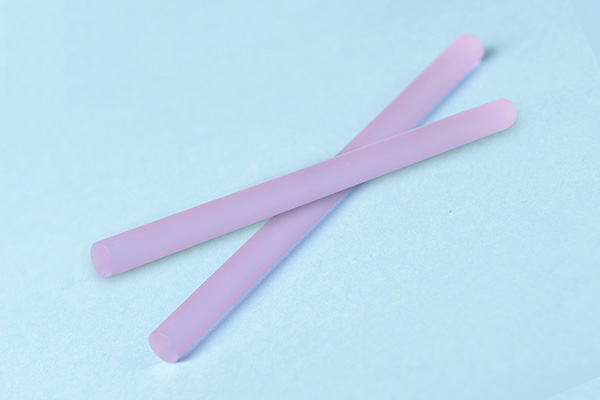

WISOPTIC provides Nd:YAG rods with the following features: different doping levels, high optical homogeneity, high processing accuracy, precise barrel grooving and wedge angle, various end cuts, various dielectric coatings, high damage threshold.

Contact us for the best solution for your application of Nd:YAG crystals.

WISOPTIC Capabilities – Nd:YAG

• Various options of Nd-doping ratio (0.1%~1.3at%)

• Various options of rods or slabs (flat, wedged, Brewster, grooved, etc)

• High optical homogeneity

• High processing accuracy

• High quality coating, high damage threshold

• Very competitive price, quick delivery

WISOPTIC Standard Specifications* - Nd:YAG

| Standard Doping Ratio | Nd%=0.1%~1.3at% |

| Orientation | <111> or <100> or <110> |

| Orientation Tolerance | +/-0.5° |

| Dimensions | Diameter: 2~15 mm, Length: 3~220 mm |

| Dimension Tolerance | Diameter (±0.05)×Length (±0.5) mm |

| Barrel Finish | Ground with 400# grit, or polished |

| Flatness | < λ/10 @ 632.8 nm |

| Surface Quality | < 10/5 [S/D] |

| Parallelism | < 10” |

| Perpendicularity | ≤ 5′ |

| Chamfer | 0.15 ± 0.025mm @ 45° |

| TransmittedWavefront Distortion | < λ/10 @ 632.8 nm |

| Clear Aperture | > 90% central area |

| Extinction Ratio | > 30 dB |

| Coating | AR-Coating: R<0.10% @1064nm |

| Laser Damage Threshold | > 800 MW/cm2 for 1064nm, 10ns, 10Hz (AR-coated) |

| * Products with special requirement upon request. | |

DOWNLOAD Technical Data – Nd-YAG

RoHS DOWNLOAD

Main Features - Nd:YAG

• High gain, low threshold, high efficiency

• Homogeneous distribution of Nd with subtle concentration gradient

• High thermal conductivity, high thermal shock resistance

• High homogeneity, low wavefront distortion

• High optical quality, low single pass loss (especially at 1064nm)

• Various modes of operation (CW, pulsed, Q-switched, mode locked)

Physical Properties – Nd:YAG

| Chemical formula | Y3-3xNd3xAl5O12 (x=Nd doping ratio) |

| Crystal structure | Cubic |

| Lattice constants | 12.01 Å |

| Density | 4.55 g/cm3 |

| Rupture stress | 1.3~2.6×103 kg/cm2 |

| Melting point | 1970 °C |

| Mohs hardness | 8~8.5 |

| Thermal conductivity | 14 W/(m·K) @20°C, 10.5 W/(m·K) @100°C |

| Thermal expansion coefficients | 7.8×10-6 /K @<111>, 7.7×10-6 /K @<110>, 8.2×10-6 /K @<100> |

| Thermal shock resistance | 790 W/m |

Optical Properties – Nd:YAG

|

Laser transition |

4F3/2 → 4I11/2 @ 1064 nm |

|

Photon energy |

1.86×10-19 J |

|

Emission linewidth |

4.5Å @ 1064 nm |

|

Stimulated emission cross-section |

2.7~8.8×10-19 /cm2 @ Nd%=1.0at% |

|

Loss coefficients |

0.003 /cm @ 1064 nm |

|

Fluorescence lifetime |

230 µs @ 1064 nm |

|

Refractive index |

1.818 @ 1064 nm |

|

Pump wavelength |

807.5 nm |

|

Absorption band at pump wavelength |

1 nm |

|

Polarized emission |

Unpolarized |

|

Thermal birefringence |

High |

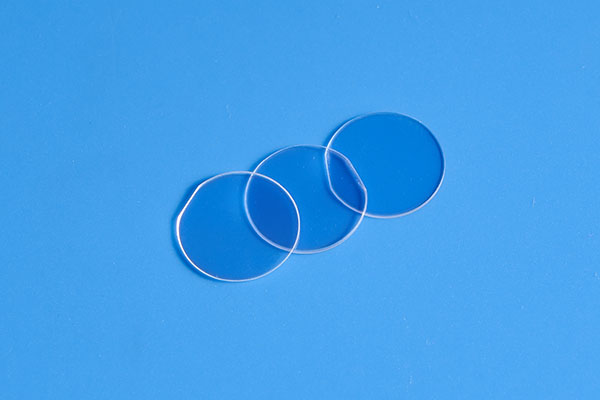

Product detail pictures:

Related Product Guide:

Our team through qualified training. Skilled professional knowledge, powerful sense of support, to satisfy the support desires of consumers for OEM/ODM Factory Yag Rods - Nd:YAG Crystal – WISOPTIC, The product will supply to all over the world, such as: Greenland, Amman, Guinea, Look forward to the future, we'll focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our in depth advantages and strive for building.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.